Relevant standards requirement

- Test Object: battery pack andsystem.

- Refer GB/T4 part 5.5.2 test method, test according to GT/T2423.17 test conditions.

- The salt solution was made up with sodium chloride (chemically pure and analytically pure) and distilled or deionized water,Its concentration is (5 + 1)% (mass fraction).

- (35 ± 2) ℃, the measured pH value is between 6.5-7.2.

- Placed the test objects in the salt spray chamber for cycling test. Each cycling duration for 24h. Spray salt solution to the test object for 8 hours under the temperature of (35± 2) ℃ , remain for 16 hours. Between the forth and the fifth hour in one cycles should be according to test requirement in GB/T 28046.1-2011, test mode with 3.2.

- Total 6 cycles testing.

- Salt spray test is not necessary for the test objects being installed in passenger, luggage or cargo compartments.

Standard

Technical Parameters

| Product Name |

Complex Salt Spray Test Chamber |

| Model No. |

HMBE8209 12(m³) |

HMBE820915(m³) |

| Internal Dimension |

W2000 X D3000 X H2000 mm |

W2500 X D3000 X H2000 mm |

| External Dimension |

W2400 X D5000 X H3000 mm |

W2900 X D5000 X H3000 mm |

| Max Load |

1000KG for battery pack |

| Temp. Range |

0℃~+85℃ |

| Temp. Fluctuation |

±0.5℃ |

| Temp. Deviation |

2℃ |

| Spray Capacity |

1~2mL/80cm2/hr (Collect at least 16 hours, take the average ) |

| Spray Pressure |

1.00±0.01kgf/cm² |

| Resolution |

Temp: 0.01℃, Humidity:0.01%R.H. |

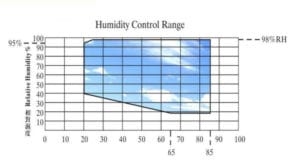

| Humidity Range |

30%–98%R.H.

|

| Humidity Fluctuation |

±3%R.H. |

| Potion PH |

Neutral 6.0~7.0 Acidity 3.0~3.1 |

| Spray Solution PH |

Neutral 6.5~7.2 Acidity 3.1~3.3 |

| Test Time Range |

1S ~ 9999H (Settable) |

| Control Mode |

Touch screen programmable control PLC, networking; mobile phone APP alarm; with USB interface, with RJ485 interface can be connected to computer control, exclusive network control software. Remote monitoring and data acquisition. |

| Internal material |

Acid and alkali resistant SUS316 material |

| External material |

Cold and heat resistant steel plate with spray coating |

| Cooling Mode |

Air cooling / water cooling |

| Total Weight |

Approx 7 Tons |

| Power Supply |

AC 380V, 55KW |

| Other Auxiliary Functions |

*Main-subsidiary type trolley for the specimen in and out of the test chamber.*Explosion-proof, Pressure relief, Smoke Exhaust, Fire extinguishing, Video monitoring. |