DESCRIPTION

This test box is mainly used for electronic and electrical products to assess whether the housing and seals can ensure the good working performance of the equipment and components during the sand and dust test

Structure and material

Material: Liner: SUS#304 high-grade stainless steel plate

Outer box: A3 steel plate electrostatic spraying

Specimen power socket: dustproof socket

Controller: touch screen controller communication control (this controller has the following multiple arbitrary setting control functions)

Adjustable dust blowing time (stop, blowing)

Cycle period: arbitrarily adjustable

Preset test time: 0.1H-9999.9H adjustable

Power on: off-on-off

With tired time function and power-off protection function

Blower: All-plastic centrifugal fan

Vacuum system: equipped with pressure gauge, air filter, pressure regulating triple piece, connecting pipe (vacuum pump is equipped separately, please specify when ordering)

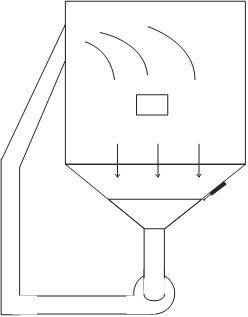

Sand and dust schematic

This equipment implements standards

La and Lb in GB2423.37-89; GB 4208-98; IEC60529. The test box is made according to the following standard requirements

The SC series dustproof test box is designed and manufactured in accordance with GB4208-93 (equivalent to IEC60529-2001) "Enclosure Protection Level (IP Code)". It is suitable for electrical products to carry out the first characteristic numbers of 5 and 6 (IPX5 and IPX6). ) Sand and dust test.

In accordance with the requirements of the standard, this test box uses an artificially simulated dust environment to inspect the dust-proof ability of the tested product. Its specific requirements and qualification criteria should be in accordance with GB4208-93 (IEC60529-2001) or product-related standard requirements.

Another note: This test box can meet the requirements of GB2423, GB4706, GB4208, DIN, household appliances, low-voltage electrical appliances, automobile, motorcycle parts shell protection level test requirements. This device cannot meet the sand dust test with wind source in GJB150.

SPECIFICATION

1. Studio size (mm): 1000×1000×1000 (length×width×height)

Approximate outer box size (mm): 1520×1320×1850 (length×width×height)

2. Inner box material: stainless steel plate

3. Outer box material: cold-rolled steel plate electrostatic spraying

4. Door: Large tempered glass observation window

5. Air duct system: unique air duct design to ensure that the box produces a non-layered vertical circulating airflow

6. Temperature in the box: 15~35°C

7. Relative humidity in the box; 45%~75%RH

8. Net nominal wire diameter: 50um

10. Nominal distance between lines; not more than 70um

11. The amount of dust in the box: 2Kg/m

12. Air velocity: ≤2m/s

13. Talc dosage: 2kg~4kg/ m³

14. Dust blowing time: 0~9999.9h can be set

15. Control system: imported high precision PID digital display instrument

16. PT100 test sensor

17: Safety protection device

a). Instrument over temperature protection function

b). Power phase loss protection

c). Leakage circuit protection

18. The wind speed is not adjustable: 0-10m/s

19. Sand dust concentration: 0-50/100/200/1000/20000mg/m³, optional. Optional.

20. Power supply: AC 220V, 50Hz

Protective device

1. Safe and reliable grounding device

2. Motor overload protection

The main parameters:

| Standard basis |

GB4208-93、IEC60529-2001 |

| Environmental conditions |

Air temperature: 0~35℃

Relative humidity: 25%~75%RH

Atmospheric pressure: 86~106kpa |

| Power supply |

Rated voltage: AC220V

Rated frequency: 50HZ

Input power: about 3KW |

| Talc dosage |

2kg/m3 |

| Power supply |

AC220V,50HZ |